ABOUT

The Injection Moulding Company

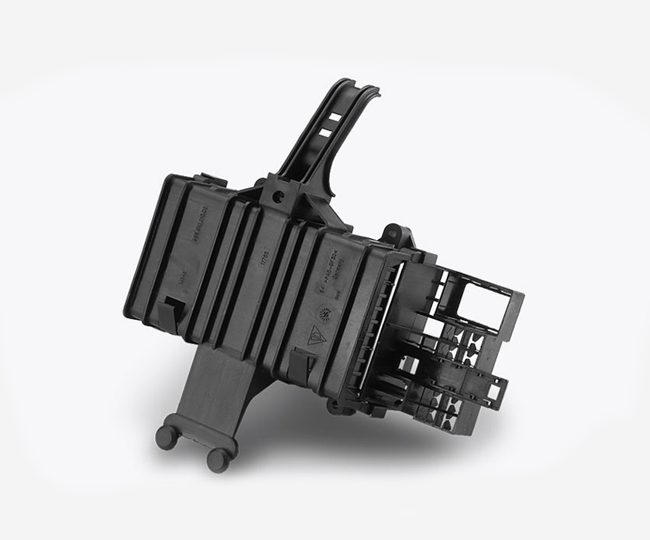

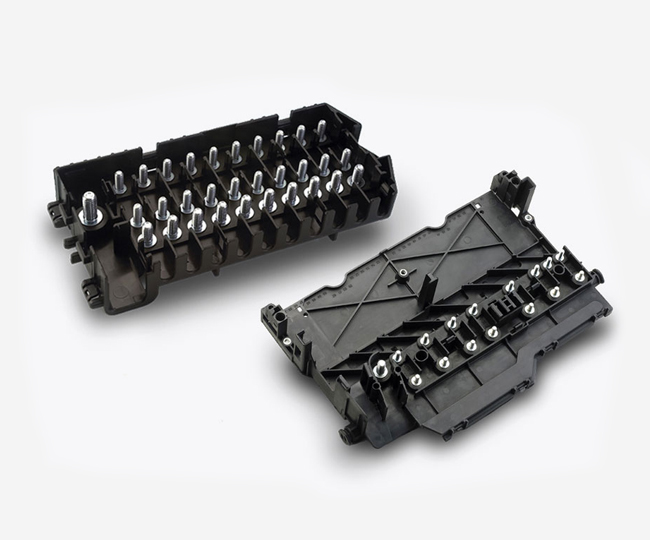

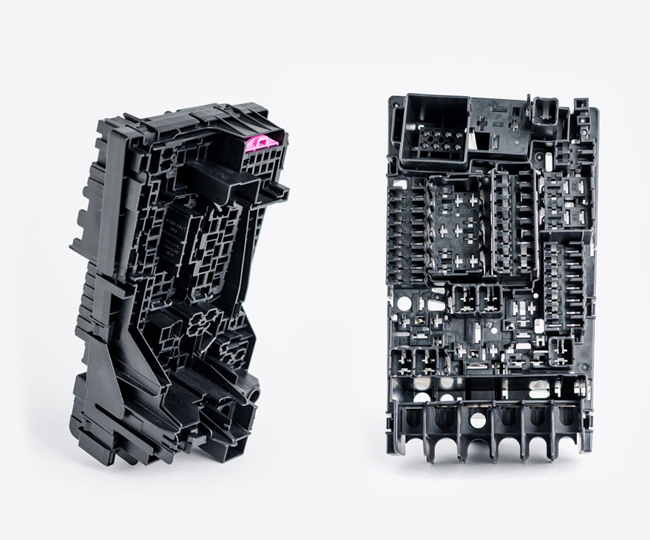

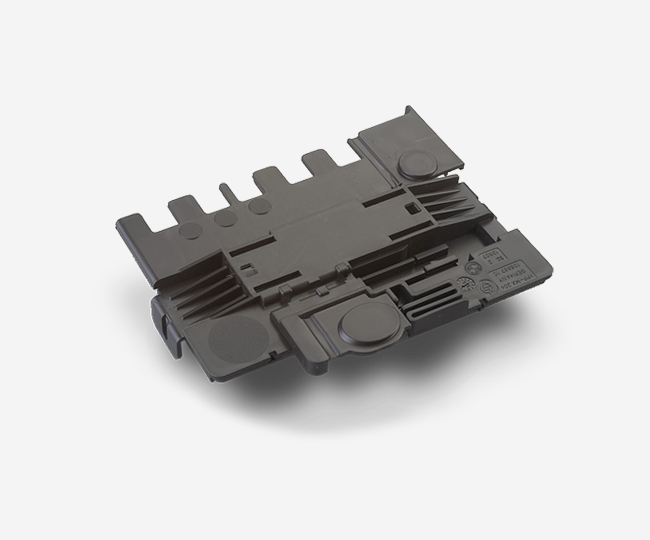

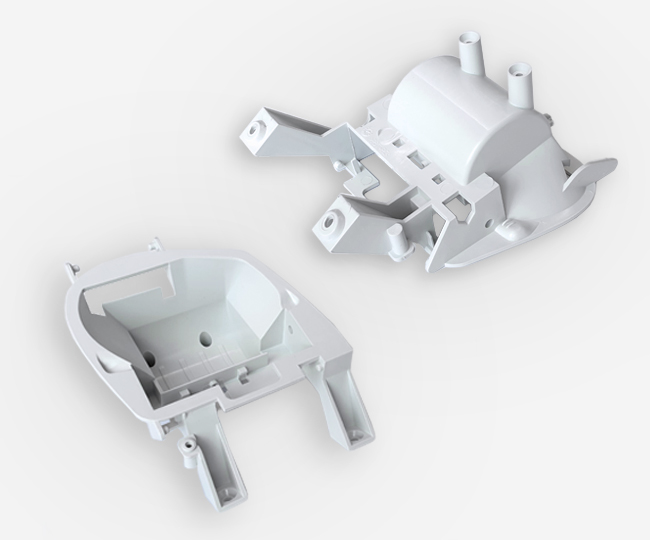

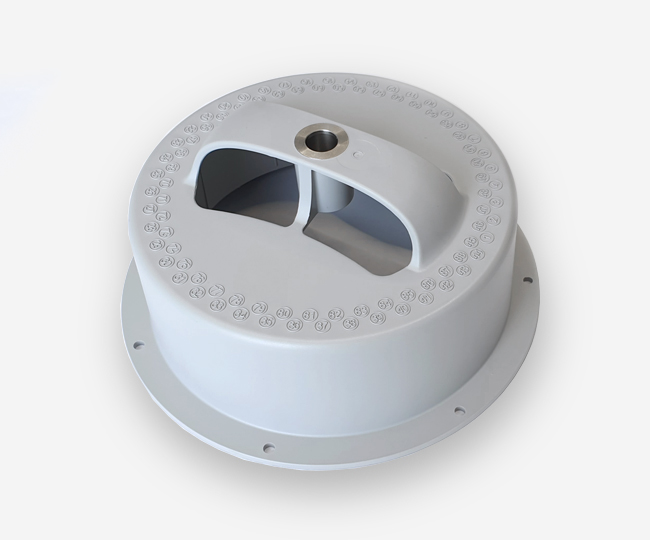

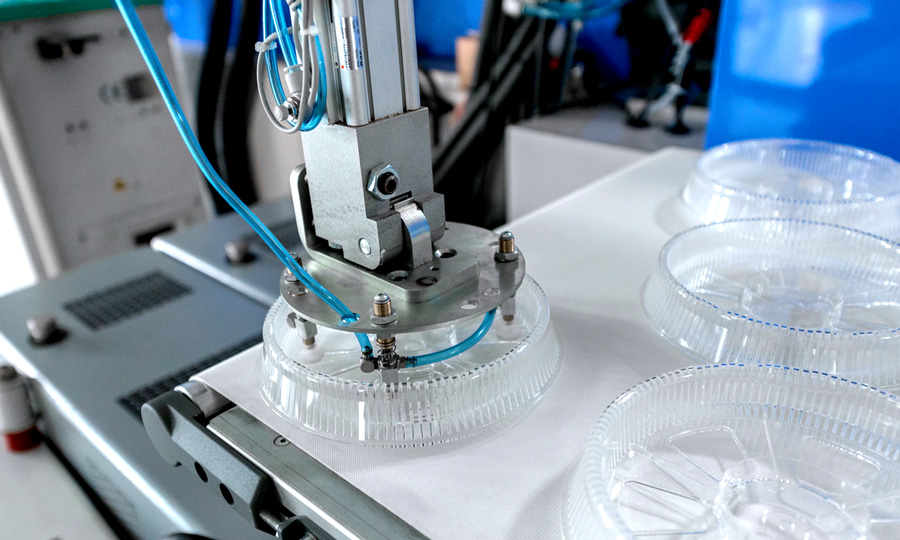

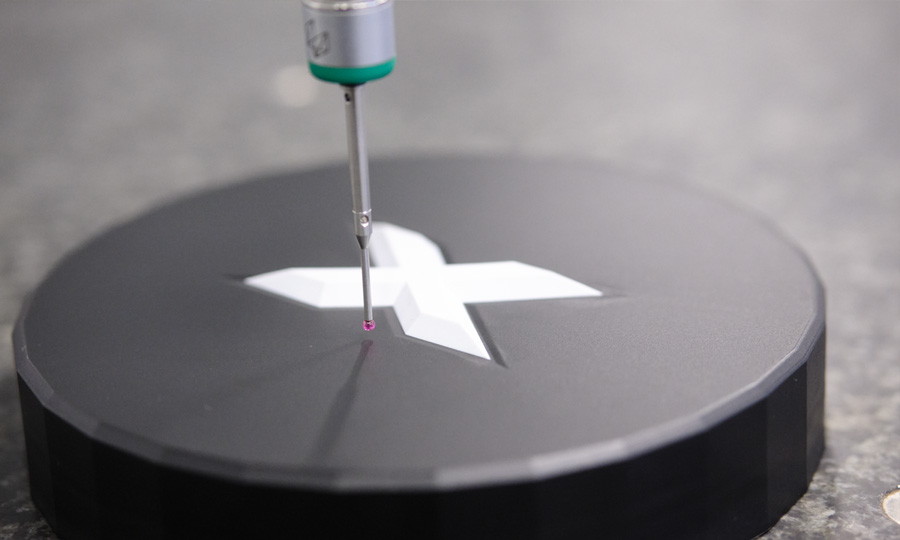

EHTP specializes in production of high precision components in thermoplastic injection. With high demand we need to have high capacity. At the core of our fully automated robotic production lines, we have the latest JSW and Engel injection moulding machines that deliver high quality parts with greater efficiency. Our factory operates 24 hours a day, 7 days a week.

In our clean and efficient facility, we provide high quality plastic components ensuring reliability and continuous workflow. Our carefully selected machines are exclusively electric and moulding high “cpk” values.

To support continuous production lines, our facilities are powered by solar panels for better energy efficiency and reinforces our environmentally conscious outlook. Our modern built factory facilitates cost effective production methods and at the same time we reduce the impact on the environment.

INDUSTRIES

Portfolio

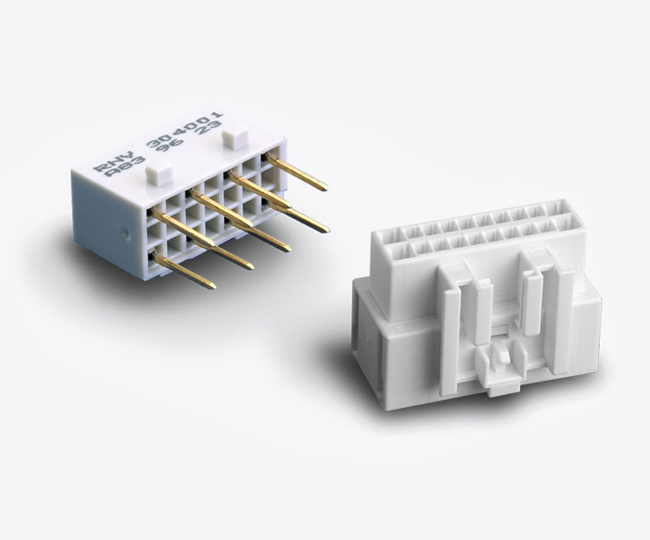

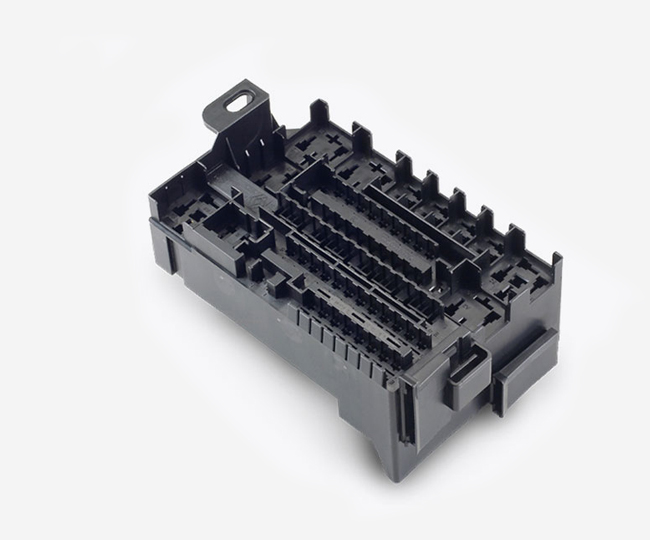

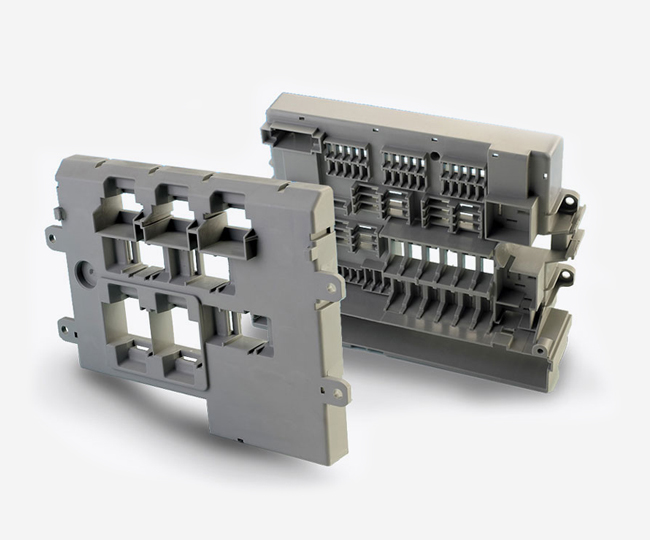

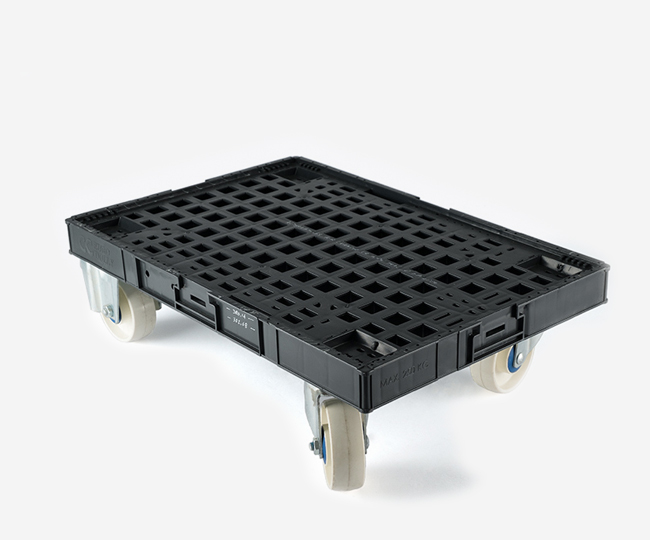

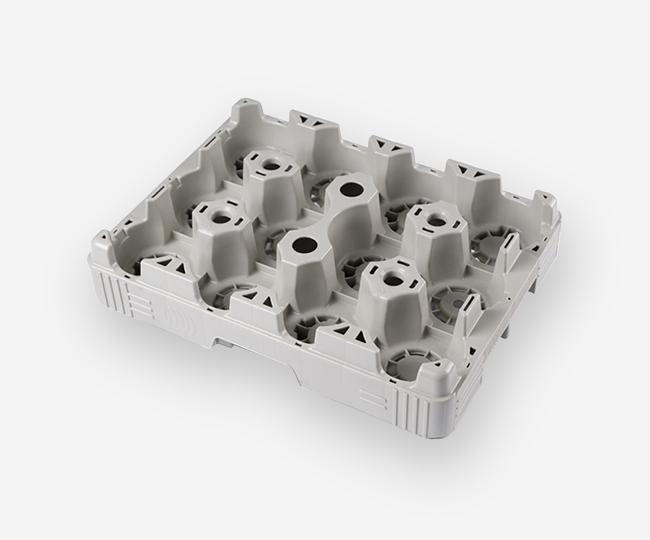

High Precision Injection Moulding: EHTP caters to industries that require high standards, exceptional quality and reliability. Our innovative plastic manufacturing solutions provide our customers with the assurance of quality, efficiency and best delivery times for the following industries: Automotive, Medical, Electro-electronics, Food & Beverage and Packaging.

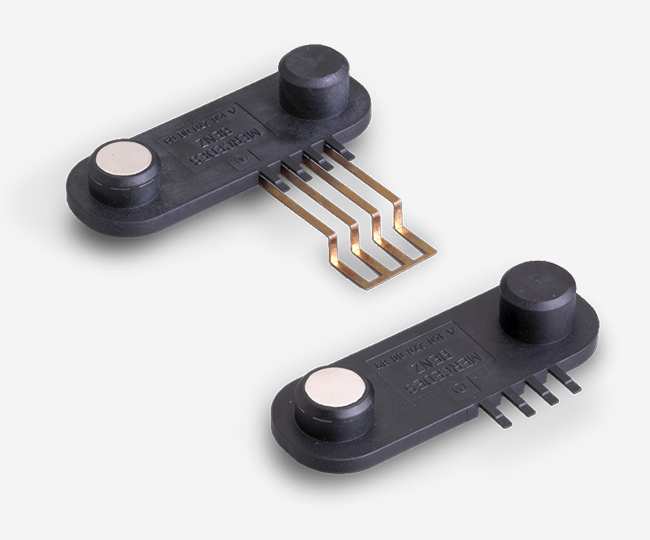

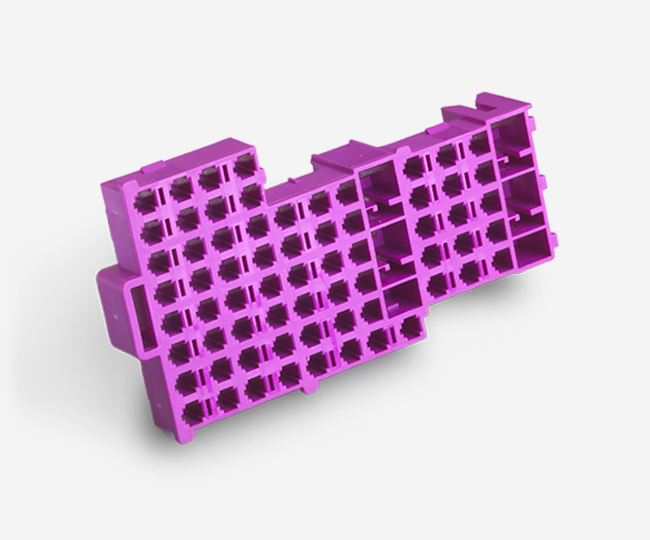

Electro-Eletronics

Food and Beverage

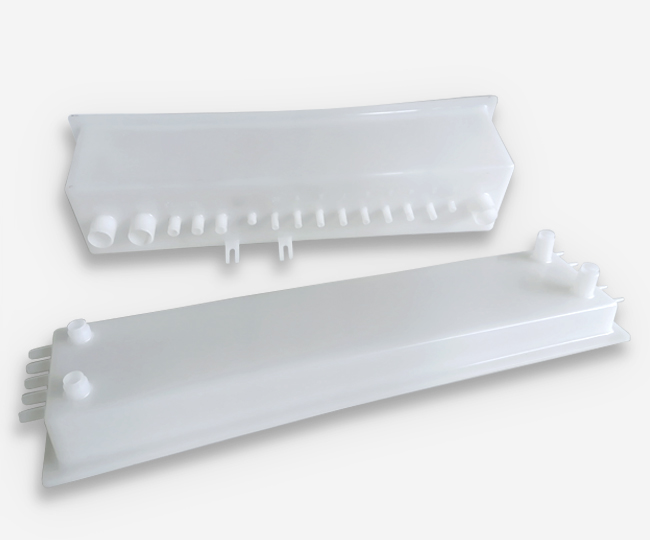

Medical

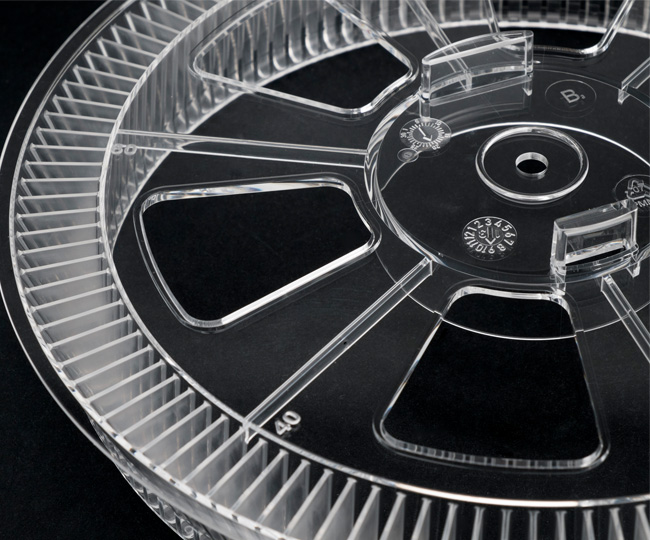

Packaging

QUALITY

& Focus

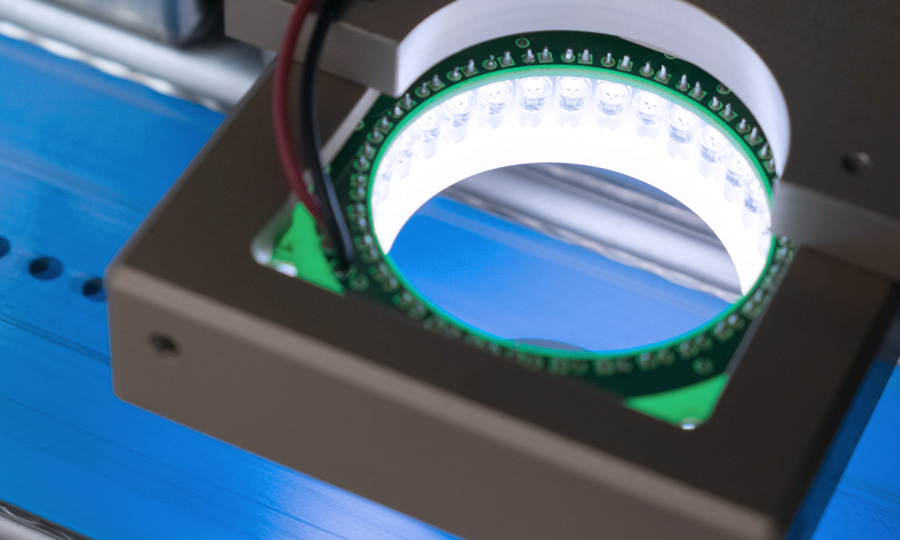

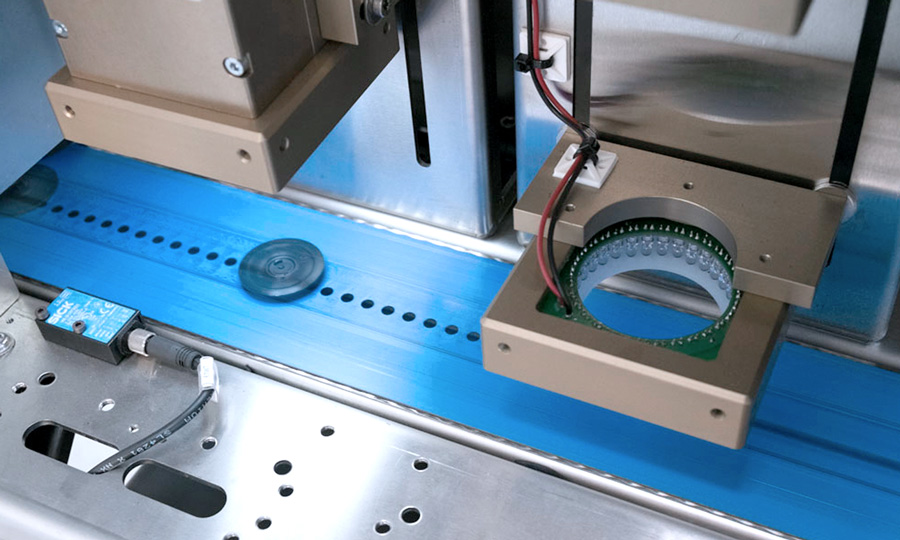

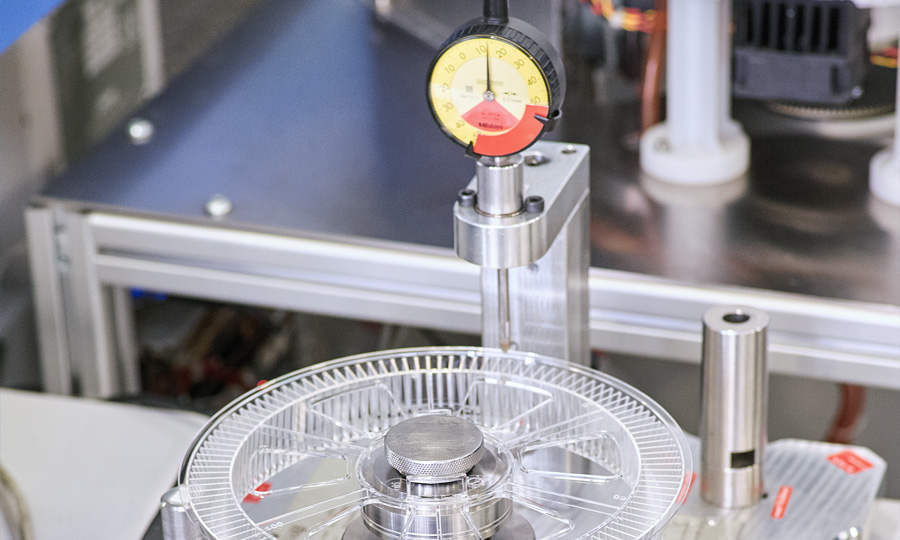

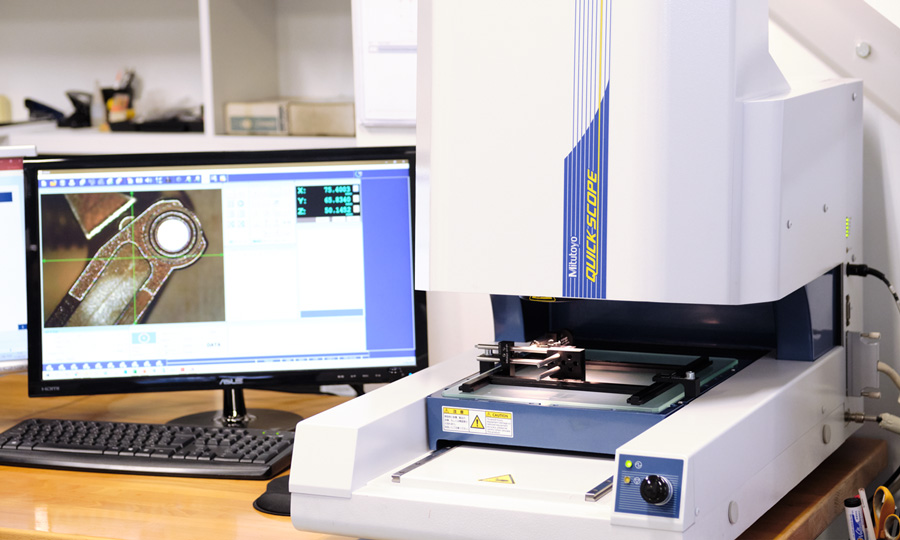

We promise our clients to work towards a lean production and zero defects. To ensure that we maintain high quality standards, we integrated artificial vision systems for quality inspection in some of our production lines to detect with real-time capability potential failure trends at the very initial stages. This allows real-time action/solutions for process and quality optimization.

We are certified under ISO 9001 (Quality), ISO 14001 (Environment), and ISO 13485 (Medical Devices) standards and are committed to maintaining an efficient and effective Integrated Management System with strict quality control.

We have also implemented an integrated automotive quality management system in accordance with the IATF 16949 standard, ensuring the excellence and precision required to produce high-quality parts. These certifications represent our customers’ trust and contribute to strengthening our competitiveness and reliability in the plastics industry.

If you want to know more about our Policies, please consult us.

Scopes

ISO 9001:2015 and ISO14001:2015 – Manufacture and assembly of plastic parts by Injection

ISO 13485:2016 – Manufacture and assembly of plastic parts by Injection for incorporation into third party medical devices.

CONTACT

Let's work together!

Adress

Complexo Industrial VANGEST

Edifício 6 | Nave A

Rua do Conhecimento 270

2430-528 Marinha Grande

Phone

+351 244 090 120